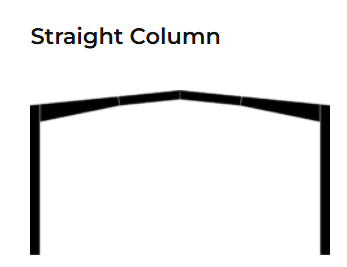

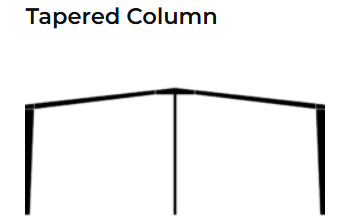

Clear Span Frames

Ideal for large, open spaces without interior support columns. Perfect for warehouses, aircraft hangars, or gymnasiums where unobstructed floor space is critical.

- Side walls can be straight or tapered columns

- Roofs can be single or double slope

- Can span up to 250’

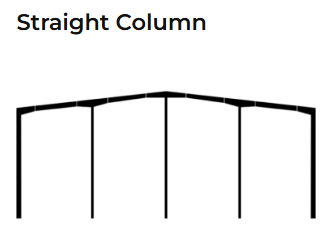

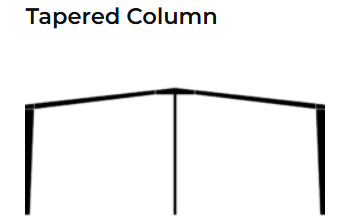

Multiple Column Supported Span Frames

Designed for larger buildings requiring interior support columns. This cost-effective option is ideal for manufacturing facilities, distribution centres, and large storage buildings.

- Comes in straight column, tapered column, and single or double slope roofs

Open Web Truss System Buildings

Open web truss designs offer outstanding flexibility, making them perfect for applications requiring the widest possible spans. These highly durable framing systems are ideal for large-scale structures such as oversized freezers, coolers, aircraft hangars, warehouses, and indoor sports facilities.

- This system can support frames to a width of 500 feet

- Truss system allows for greater strength and stiffness than rigid clear span frames while using less materials

Crane System

Crane systems are specifically designed to meet the added load requirements of heavy industrial buildings. They also feature large areas of uninterrupted interior space to further accommodate production machinery and equipment.

Our wall panel options offer both durability and aesthetic appeal to meet your building’s functional and visual needs.

- Standard Metal Wall Panels

Strong and cost-effective, these panels provide excellent weather resistance and durability for industrial and commercial buildings.- Applications for Roofs, Walls, Fascia’s, Soffits

- Architectural Metal Wall Panels

Designed for enhanced visual appeal with customizable profiles and colors. These panels are ideal for office spaces, retail locations, and modern steel structures.- Applications for Walls, Fascia’s

- Insulated Metal Wall Panels

Combining insulation with durable metal panelling, these provide superior energy efficiency and thermal performance.

We offer roof panel solutions tailored to meet your climate and structural requirements.

- Standard Metal Roof Panels

Durable and easy to install, these panels provide reliable protection against the elements.- Applications for Roofs, Walls, Fascia’s, Soffits

- Architectural Metal Roof Panels

Combining strength with a sleek appearance, these panels are perfect for commercial buildings where aesthetics matter.- Applications for Roofs, Walls, Fascia’s, Soffits

- Insulated Metal Roof Panels

Designed for superior thermal performance, these panels improve energy efficiency and reduce heating and cooling costs.

Customize your steel building with a variety of accessories that improve functionality, energy efficiency, and comfort.

- Insulation Options

Choose from fiberglass, spray foam, or rigid board insulation to enhance energy efficiency and maintain indoor temperatures.- High R value insulation systems (systems can provide R values in excess of R40 and provide excellent condensation control)

- Doors

From roll-up garage doors to walk-in entry doors, we offer multiple options to meet your access needs. - Windows

Maximize natural light with fixed or operable window options, available in various styles and sizes, glazing options and design pressures. - Other Accessories

Customize your building further with ventilation systems, fans, solar panels, gutters & downspouts, skylights, mezzanines, and more to enhance comfort and functionality.

Choose from a wide range of durable, long-lasting colour options to customize the look of your steel building. Our coatings are designed to resist fading, chipping, and corrosion, ensuring your building maintains its professional appearance for years to come.

When designing your prefabricated steel building, several key parameters are considered to ensure structural integrity, safety, and durability. These parameters vary depending on the specific location where the building will be erected. Key climatic design loads include:

- Snow and Rain Loads

Each region/location has specific building codes that define snow and rain load requirements based on historical weather data. Snow and Rain loads account for the weight of accumulated snow and rain on the roof, while rain loads also ensure proper drainage and prevent water buildup. By factoring these loads into the design, we ensure your building will withstand regional weather conditions year-round. - Wind Loads

Wind load requirements differ from one region to another, with areas prone to higher winds (like coastal or hurricane-prone regions) requiring more robust design considerations. Wind load calculations take into account local wind speeds, direction, and the building’s height and shape, ensuring your steel building remains stable during severe weather events. - Seismic Loads

For regions located in seismic zones, seismic load considerations are crucial to the structural integrity of the building. These loads are based on the magnitude of earthquakes that could occur in the area. Steel buildings are designed with seismic resistance in mind to minimize damage in the event of an earthquake, ensuring safety and long-term resilience. - Collateral Loads

The collateral load included in the design of a pre-engineered steel building is a dead load to cover the additional loading requirements for mechanical, electrical, or any other services or equipment the building requires. A proper assessment of collateral loads ensures your steel building can support both its permanent and temporary loads without risk of failure - Limit State Design

Limit state design refers to the method used to ensure a building can handle extreme conditions without reaching a point of failure. This involves designing the building to meet safety standards under both normal and exceptional conditions. By using limit state design principles, we ensure your building remains functional and safe throughout its lifespan.

A solid foundation is the cornerstone of every successful steel building project. We offer a range of engineered foundation solutions tailored to your site, soil conditions, and structural needs. Whether you’re building on bedrock, soft soils, or uneven terrain, we provide complete turnkey foundation systems that ensure long-term stability and performance.

Concrete Foundations

Our prefabricated steel buildings are typically anchored to high-performance concrete foundations. These are designed to handle heavy structural loads while providing a level, durable base. All concrete work meets or exceeds local code requirements, and we manage the entire process—from site prep and formwork to pouring, curing, and final inspections.

Column Base Options

We offer two primary base connection types to suit various building applications:

- Fixed-Base Columns: These are anchored rigidly to the foundation, minimizing lateral movement. Ideal for high-load or wind-prone applications like industrial facilities, commercial buildings, and hangars.

- Pinned-Base Columns: Designed to allow slight rotational movement, these are cost-effective and easier to install—often used in agricultural, storage, and warehouse structures.

Anchor Bolts

Our buildings are secured with precision-engineered anchor bolts, embedded directly into the foundation. These bolts ensure accurate alignment and structural stability. We supply detailed anchor bolt plans and templates with every building kit to support proper installation and safety compliance.

Alternative Foundation Types

We also offer non-traditional foundation systems for sites with special requirements:

- Screw Piles: Ideal for quick, low-disruption installations on soft or variable soil conditions. Screw piles are steel shafts with helical blades that are screwed into the ground, offering strong load-bearing capacity without the need for concrete. Perfect for remote areas, environmentally sensitive sites, or seasonal buildings.

- Pile-Driven Foundations: These involve steel or concrete piles being driven deep into the ground to reach stable soil layers. Commonly used for heavy-duty applications or locations with poor surface soil. Pile-driven systems deliver exceptional vertical load support and are engineered to handle challenging subsurface conditions.

All our steel buildings are manufactured to meet CSA W47.1 standards for fusion welding of steel. This certification ensures that our engineering, manufacturing, and fabrication processes meet rigorous requirements for:

- Pre-engineered steel buildings

- Building components

- Multistorey structural buildings

- Self-storage warehouses